The Canterbury earthquake of September 4 has provided an opportunity for the manufacturer of timber water storage tanks in New Zealand, Timbertank Enterprises Ltd., to study the impact this unique event has had on their tanks used in fire systems, town supply and industrial installations.

Timbertanks' managing director Justin Jordan and the company's

consultant engineer Waldo Granwal, met with engineers from Holmes

Consulting Group and Canterbury University College of Engineering,

to discuss the impact on tanks and timber structures of the

earthquake.

There were numerous reports of damage and collapse to water

storage tanks of all makes and while the study will be ongoing,

some initial findings and conclusions were reached. A major

conclusion is that tanks in the Christchurch region will in future

require special design.

"The earthquake was very localised and characterised by the

underlying very deep alluvial shale layer creating an unusual

action of a strong pressure wave followed by a long period of low

frequency secondary shear waves that caused most of the damage in

water tanks," said Waldo. "It was well beyond any previous

expectations specified by the Code at the time for the design and

construction of such tanks. It exceeded it by a large margin -

three to four times more than would have been expected.

"We achieve the code standard as a minimum. If tanks were built

to exceed the standard to withstand such a quake, the cost factor

would outweigh the economic benefit - double the cost. Perfection

is attainable, but it comes at a cost."

Timbertanks inspected a total of 25 tanks that it built over the

last 30 years in the region affected by the earthquake. Of these,

seven tanks lost their water as a result of the 'quake. The

remaining 18 performed as expected - shuffling approximately 20mm

as base isolated tanks are designed to do.

Four out of the seven affected tanks had base isolation

compromised by rigid pipe attachments or illegal ground

obstructions, leaving three tanks that the company "would have

liked to perform better." Certain size diameter tanks only were

affected, others around the epicentre that performed perfectly had

a different diameter.

The locations of all the tanks are shown on the attached map of

the region, showing their proximity to the epicentre and to those

areas where liquefaction affected structures the most. Three were

in the Hornby/Islington area.

It took until a month out from the event to firstly inspect

tanks, then start understanding what had happened and work through

the issues to try and find answers. It evolved with different

inputs being received almost every day. Subsequent after shocks

also exacerbated the situation at a couple of sites.

"Of course we would have preferred the tanks to have performed

better, but with the magnitude of the 'quake being more than anyone

expected and some owners not maintaining the requirement of a base

isolated system... quite frankly at this level we would almost

expect failure," said Justin.

"We were caught out by the extent of the sloshing - the wave

velocity acceleration which caused the tank to move around," he

added. "In all of this, we're learning new things and it takes a

while to understand what happened and then translate into what can

we do better - for us to set up our tanks so they can slide freely

and control the wave slosh.

"Everyone is trying to react quickly to this earthquake but we

also have to ensure we move correctly - because we may have to

change our design as we learn more."

An initial report by AON New Zealand - the Sprinkler

Certification Authority - on tanks inspected after the event, noted

however that the current method of piping Timbertanks via a buried

pipe rising into an anti-vortex plate in the centre of the tank

'appeared sound'. The consequence of the pipe work not being

articulated only caused further damage.

"We agree with the report from AON regarding sprinkler system

performance, of the need to introduce flexibility into piping

design where deflection due to seismic movement is anticipated. In

the Christchurch situation we need to ensure these flexible

knuckles and similar critical features are built in," he said.

The team spent six days collecting information. All the damaged

tanks were fire tanks, all of a similar size over 10-13 metres

across, which appears to equate to the sloshing frequency that

occurred with the water over periods of about three seconds. (Steel

tanks of the same proportions had the same problems).

"We acknowledged that the integrity of fire protection systems

is essential for such as major hospitals, CD headquarters, prisons

or airports. We are working with the Fire Protection industry to

re-establish those tanks as soon as possible, within the required

code."

So is there an answer to this whole earthquake problem, given

that the law requires that a fire tank be designed to retain its

contents and be useable for purpose?

"Anyone who claims that a tank designed to earthquake code

1170.5 would have survived this rogue event does not understand the

whole picture!" says Justin. "Structures susceptible to these large

secondary waves will need special attention beyond code 1170. In

the past, base isolation has neutralised tank slosh - so in

Christchurch a tank with a diameter at risk will have dampening

baffles installed."

"Also in the past we have found it very difficult to go to a

customer and say we believe it's a very good idea that you spend

some money to make your tank earthquake ready. In the 30 years

since it was built, if a tank has not been maintained in a

satisfactory manner to meet the current code, you can expect

problems. And they occurred. This has highlighted the need for more

than normal maintenance to preserve a tank and make it earthquake

ready.

"We will look at better signage around tanks to ensure they are

kept free of debris, earth, structures built up against them etc.,

which would inhibit the base isolation from performing as it

should.

"We will strongly recommend that companies have a maintenance

contract which will provide a warrant of fitness that the tank

meets all the codes for performance in earthquake according to the

existing standards, that they meet the designer's and

manufacturer's specifications for purpose."

Could this happen to other large Timbertanks around the country

- for example large timber Council reservoirs?

"No we don't believe so," said Justin. "We had a tank at

Templeton where the highest reading of the earthquake was taken and

it is working today. The phenomenon that amplified the 'quake in

Christchurch is not to our current knowledge present in any other

location."

As the chaos of Canterbury recedes, a responsible review of

existing clients and their tanks will be a key aspect of

Timbertanks' future work with the Holmes Consulting Group to assure

earthquake readiness of the product. Their design analysis may

evolve to indicate a change to code specifications.

"Any designer is expected to adjust upwardly if present

knowledge has emerged which suggests otherwise - we are obliged to

do just that."

In a recent statement, United States company Caldwell, which has

been building water tanks since 1887 stated: '...only a tank

manufacturer fully understands the structure's design and ongoing

needs that ensure optimal life. Full-service tank manufacturers now

offer extended warranties on new tanks, provided that the tanks are

regularly cleaned, inspected and repaired. Safety improvements and

upgrades are also critical to the tank's long-term usefulness. Life

cycle cost comparisons based on a 40 year time frame fail to

recognise that a well designed tank can be expected to provide

useful service for more than a century.'

Justin adds - "there is a significant cost to upgrade a tank to

meet new conditions and we will be tackling it on two fronts. We

are determined to hold on to our base isolation."

Why did 18 tanks withstand the 'quake? Those that came through

with minimal or no damage related to their locale e.g. they were on

the hillside; they were base isolated and fit for purpose. Large

Timbertanks' water storage tanks in the region at West Moreland and

Springhill, also one in Ashburton, suffered no damage or loss of

function as a result of the earthquake.

Timbertank performance during Darfield 2010 earthquake

- comments from a report by Trevor Kelly - Holmes Consulting

Group

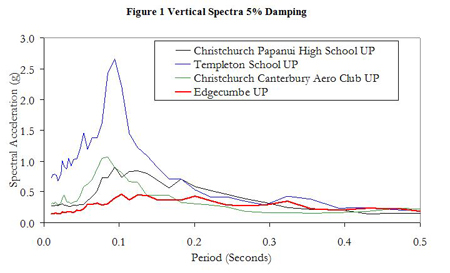

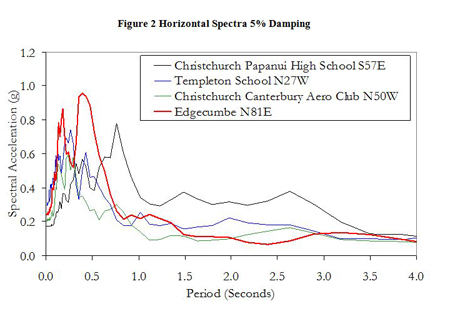

'The Christchurch earthquake motion at the sites where tanks

failed had a combination of high energy content in the long period

range, presumably due to underlying deep alluvium, and high

vertical accelerations in the short period range. The long period

motions cause high surface waves in the tanks which apply large

convective forces to the side of the tank. As these forces are

applied high up the staves, they tend to cause overturning rather

than sliding. This mode of response is undesirable as it permits

the line to extrude beneath the staves where it is damaged.'

'Tank evaluation procedures were developed in the 1990s

partly using observations from the most severe earthquake to which

they had been subjected up to that time - the 1987 Edgecumbe

earthquake. The Christchurch sites at which tank failure occurred

had much greater demands than Edgecumbe in some respects.' -

Holmes Consulting Group

Earthquake Location Map (PDF) showing location of water

tanks which failed and those which survived